New X-Carve project: Soap Dish

Working with the X-Carve has been a lot of fun. A while back I 3d printed the “Soap Holder by piuLAB“, and figured something similar would be great to route.

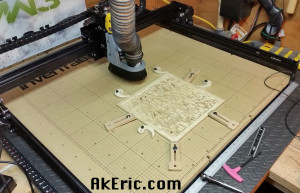

Took some time in Maya generating a pleasing voronoi pattern for the top of my soap dish, which I cut out of alder, and the bottom out of some red oak:

Generated the gcode in MeshCAM, and use Chilipeppr to send it to the X-Carve. Still a lot of learning:

- For the top:

- Used a 1/8″ 1-flute upcut endmill at 120″/min, 1/16″doc, 1/16″ stepover, Dewalt611 at 1.5, based on chipload calculators. It seemed to cut just fine. but as you can see (if you zoom in) there is vertical banding on the Z. After posting to the forums, the consensus is I’m cutting too fast. So… I’ll slow it down next time 😉

- It didn’t cut all the way though, so I had to use an x-acto to cut out the rest of the pockets. Either I need to trick it into thinking my material is thicker, or do more tuning on my Z-steps.

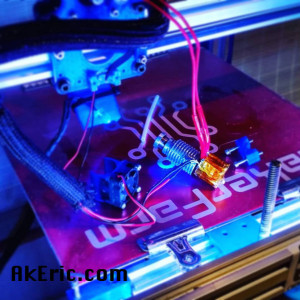

- For the bottom:

- Used a 1/4″ 1-flute upcut endmill at 120″/min, 1/8″doc, 1/8″ stepover, Dewalt611 at about 2, based on chipload calculators. It seemed to cut just find as well using a conventional climb cut on the rough pass, but on certain sections I got a lot of chugging. Again, too fast. Slower next time.

When it was done I applied some stain to the top, and sealant to both, and came up with this:

Not too bad all things considered

You can download the STL’s from Thingiverse here for routing, or 3d printing.