Building the C-Bot 3D printer: Part 16 : Assembly Updates

Jump to C-Bot blog index to see all the posts.

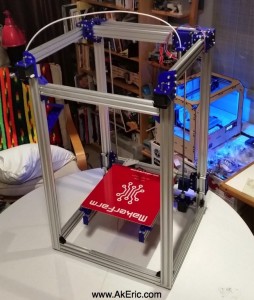

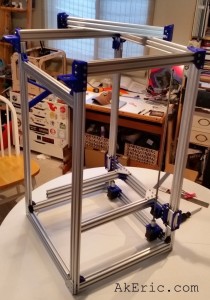

While I struggle with getting my Z-steppers to work, I did some frame upgrades:

- I hadn’t ordered enough of the OpenBuilds ‘Black Angle Corner Connectors‘ : I needed 18, I bought 8 (not sure how I missed that)… Mason needed extras as well, so he placed a big order, and I got my ten in today. So, I swapped out my printed corners on both the bottom of the frame, and the parallel arms under the HPB with the new corners. Metal FTW!

- The 8x 55mm M5 bolts that held the wheels onto the Z-gantry weren’t long enough: I couldn’t actually got a nut on the back-side. Mason experienced the same issue, and picked up two 10-packs of 60mm M5 bolts and gave me one: I went through the process, one at a time, of removing those bolts from the wheel assembly on the HPB, and swapping it for the new 60mm version, with a locknut on the end. I held all the existing spacers, wheels, and shims in place (so they wouldn’t fall all over the floor when I removed the bolt) with tape on the bottom: Worked great!

Thoughts on my Z-stepper issue:

- The A4988 drivers (that came with my Rumba ) ‘continuous current per phase’ is 1A (see link). The DRV8825‘s (like what Mason uses) are 1.5A. I’m wondering if that 50% boost would be enough to lift the z-stage? I found a 5-pack on Ebay for $13, so those are on order. But it can take up to a month: Mason may have a spare, and if so, I can test this out and see if the extra power is worth it.

- I spent a good amount of time making sure my rear Z-extrusions were the exact width apart, and futzing with the HPB Z-stage brackets: I can now lift the gantry with one hand with little resistance. I also made sure the Z-steppers were exactly below the ACME lead-screw holders: I can now get the HPB to lower, just not raise (without help from my hand). So again, I hope the DRV8825’s will resolve this lifting issue.

Time tonight: About 2 hours.

Jump to C-Bot blog index to see all the posts.