Building the C-Bot 3D printer: Part 19 : First print!

Jump to C-Bot blog index to see all the posts.

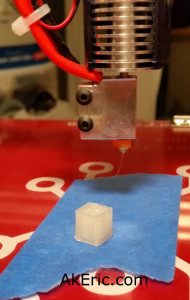

May as well show the good stuff first:

Even though the electronics still look like a giant pile of spaghetti out the side of the bot, there wasn’t much left stopping me from actually printing something. But, a few things still needed addressed:

- My build-platform wasn’t remotely level, it was drooping way too much on the front. With the help of my wife and son, I loosened up all the bolts holding the cantilevered 20×40 beams to the Z-stage, had my son slightly lift up on the end of it, and I re-tightened everything while my wife helped hold a wrench on the rear of the nuts where needed: That got me able to level it with some z-endstop adjustments.

- Based on where the hot-end homes, there’s a 2mm X & 25mm Y offset from the corner of the build platform (calculated my manually moving the toolhead on X&Y via the LCD to the corner of the build platform). I couldn’t figure out where in Marlin to enter these values: Obviously the head needs to move to this position from home and ‘start’ the print there, as 0,0,0. I slice using Simplify 3D, and I finally found these offsets in the “G-Code” section of the Process window, under “Global G-Code Offsets”.

I also needed to configure Simplify 3D to actually recognize this machine: Luckily version 3.0 came out just yesterday, and has a new machine ‘Configuration Assistant’ that made the process of ‘building’ my machine pretty easy.

From there, I imported a simple 1cm calibration cube, slapped some blue painters tape on my build platform, and fired it off. It’ immediately started moving, but not extruding: Come to find out, even though I had all my stepper wiring in the Rumba the same, I had to flip the harness on the Bowden extruder 180 to get it to extrude the direction. With that resolved, take two worked flawlessly: A few minutes later, a tiny 1cm cube appeared:

This was printed with a 1.0mm E3d-v6 Volcano nozzle, at 500micron layer height. Beefy! Surprisingly using my calipers, it was within .02mm tolerance on all axes: Not bad for a first print!

Safe to say I’m pretty happy that it ‘just worked’ on the first try. Now that I know it works I’m going to clean up all the wiring next, then get into the print calibration phase.

Jump to C-Bot blog index to see all the posts.