Repairing The Replicators HBP Cable

About nine months ago, I blogged about how the cable to my Makerbot Replicator’s heated build platform (hbp) fried. Their support was really responsive and shipped me out a new cable that fixed the problem. Well, it fried again. And if something breaks twice, I start to think about how I can make it ‘better’.

Took me a while to understand what went wrong, since from the top it looked just fine:

But after removal, the problem was plainly visible:

After checking the forums, there were several suggestions from knowledgeable users to make a separate connection for the main positive and negative leads, using 14-16 gauge cable. When I went to the local electronics store, I could only find connectors in 18 gauge, or 12. I went with 12. Which is huuuuge for this, but hey, sometimes you have to work with what you have 😉

The first step was to use a Dremel cutting wheel to hack off the positive & negative connectors:

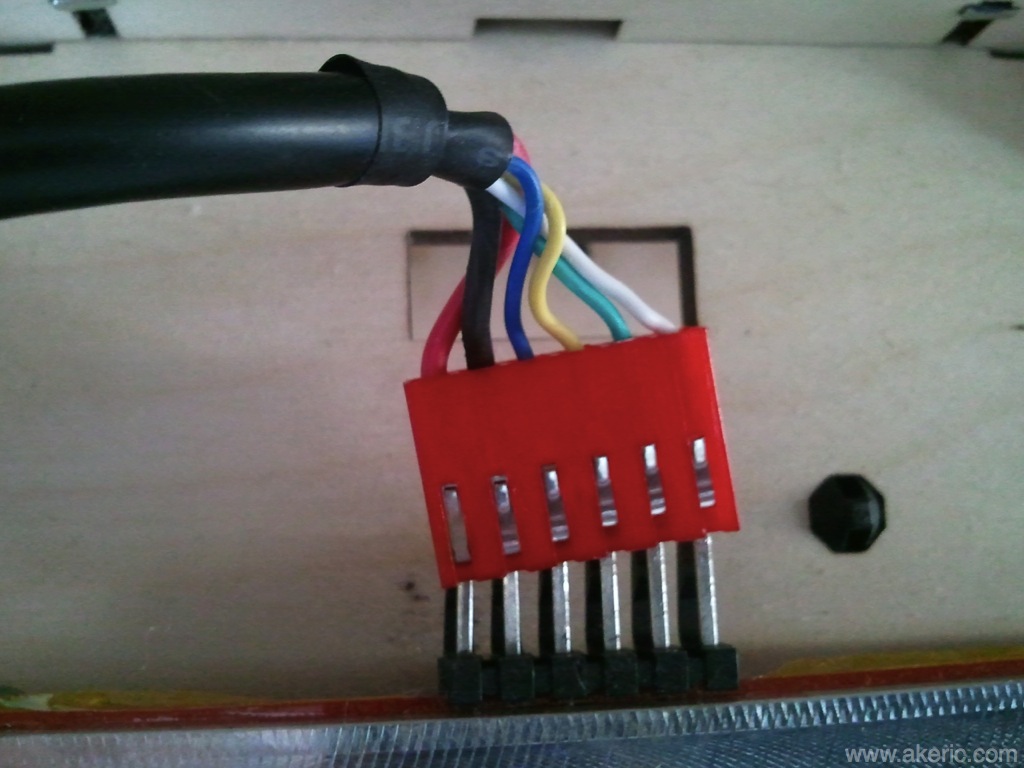

Since the connector I purchased wasn’t long enough to reach the Mightyboard, I had to solder on some (slightly smaller) extensions. This also shows off the actual connector point itself: This allows me to disconnect the whole hbp from the Mightyboard, for future removal if needed. This section sits directly under the hbp itself (when final cable routing is performed).

I ended up wrapping the whole thing in heat-shrink tubing.

The next tricky bit was soldering the 12-gauge wires to the hbp itself. To make room, I bent the left-most lead over. And to keep all the twisted strands from shooting all over the place, I tied a noose around each using the wire from a twist-tie:

Next came the soldering:

After which I removed the nooses. Finally I wrapped them up in electrical tape, and reconnected everything on both ends of the cables (no pic of the Mightyboard connection, but it’s pretty much the same as before, just with two bigger cables running into it):

I was a little scared to fire it up and start heating the platform, but it performed flawlessly. And with the larger gauge cables, heats up faster too. If things are still working nine months from now, I guess the fix worked 😉

So did this work??? Mine just fried.

It’s been 10 months, and I don’t print with ABS or heat the platform too often, but last I did it worked fine.

Dude! Thanks for posting the pic of the heated bed connector! Save me a grip of time on reassembly of my bot as I replaced my connector and forgot to make note of the wiring order on the 6 prong connector. I ended up replacing with 2x 3 prongs as that was all I could source locally. Alas, thanks again and keep up the sweet blogs yo.

~M